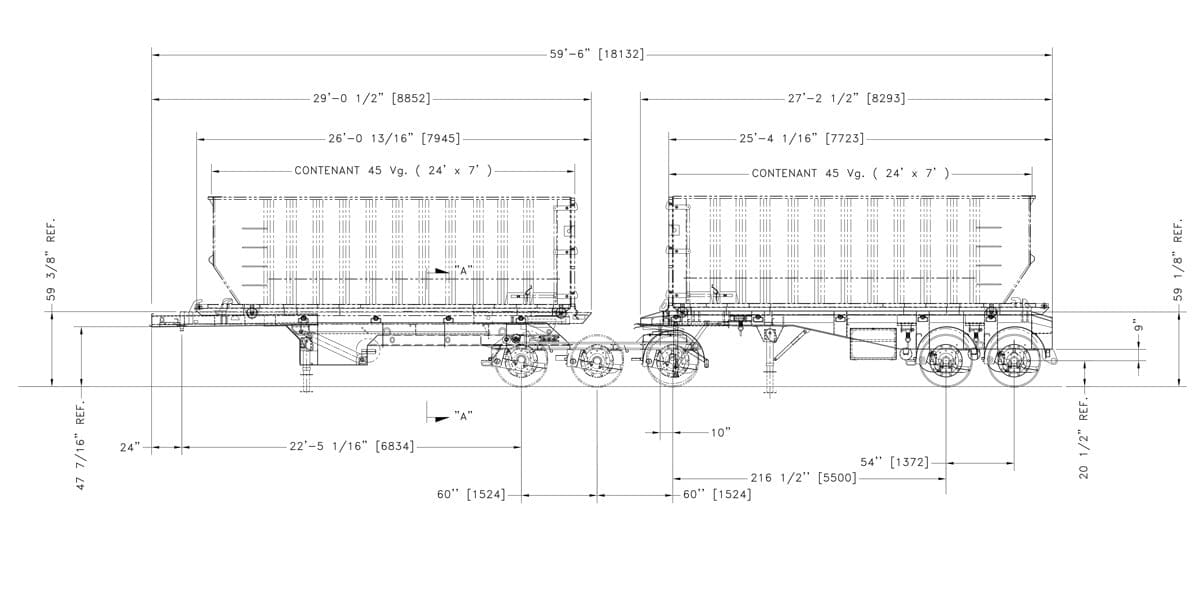

Maximize your transport capabilities with Chagnon’s B-Train Roll-Off Trailer. With a legal carrying capacity of 50,000 lb, it safely doubles your load. The standard configuration includes a primary 3-axle trailer equipped with a 60,000 lb roll-off system and a secondary 2-axle trailer (legal carrying capacity of 25,000 lb).

3 possible configurations:

- Live lead trailer, Dead rear trailer

- Dead lead trailer, Live rear trailer

- Live lead trailer, Live rear trailer

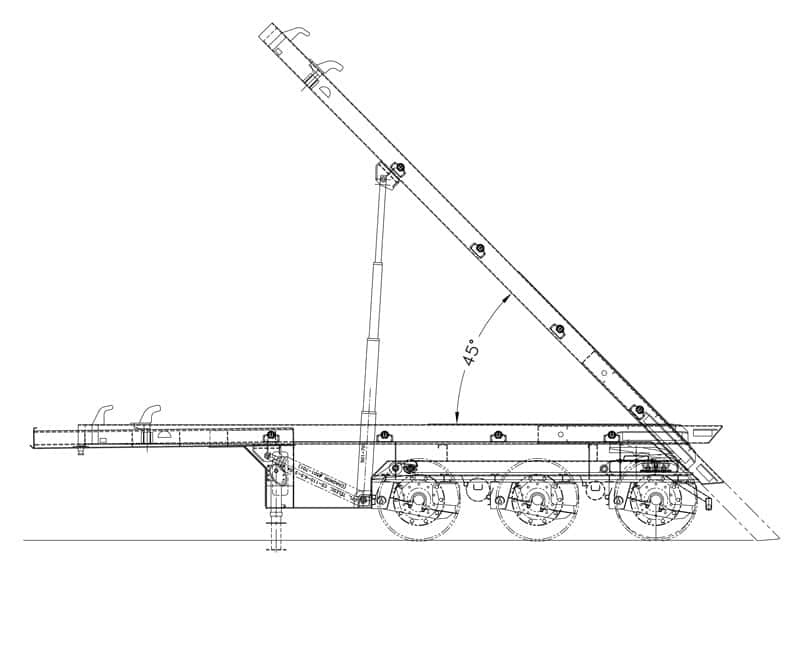

The Chagnon B-train is designed for safe, easy and reliable operation:

- Detachable axles

- Load containers on pup from the front or rear.

- Crochet d’arrimage conforme à la norme 10-CCS avec treuil.

- Greater spacing between lift cylinder at the base increases system rigidity and stability.

- Prop for easy and safe mainteance.

- External valves and controls.

- 4 configurations possible.