Maximize your efficiency with Chagnon’s 4-axle Double Roll-Off Trailer. Designed for the safe and rapid transportation of two roll-off containers simultaneously, this trailer boasts an impressive lifting capacity of 60,000 lb. Facilitating easy loading and unloading without the need for additional equipment, the Double Roll-Off Trailer is an optimal solution for those looking to increase transport capacity while maintaining safety and ease of use.

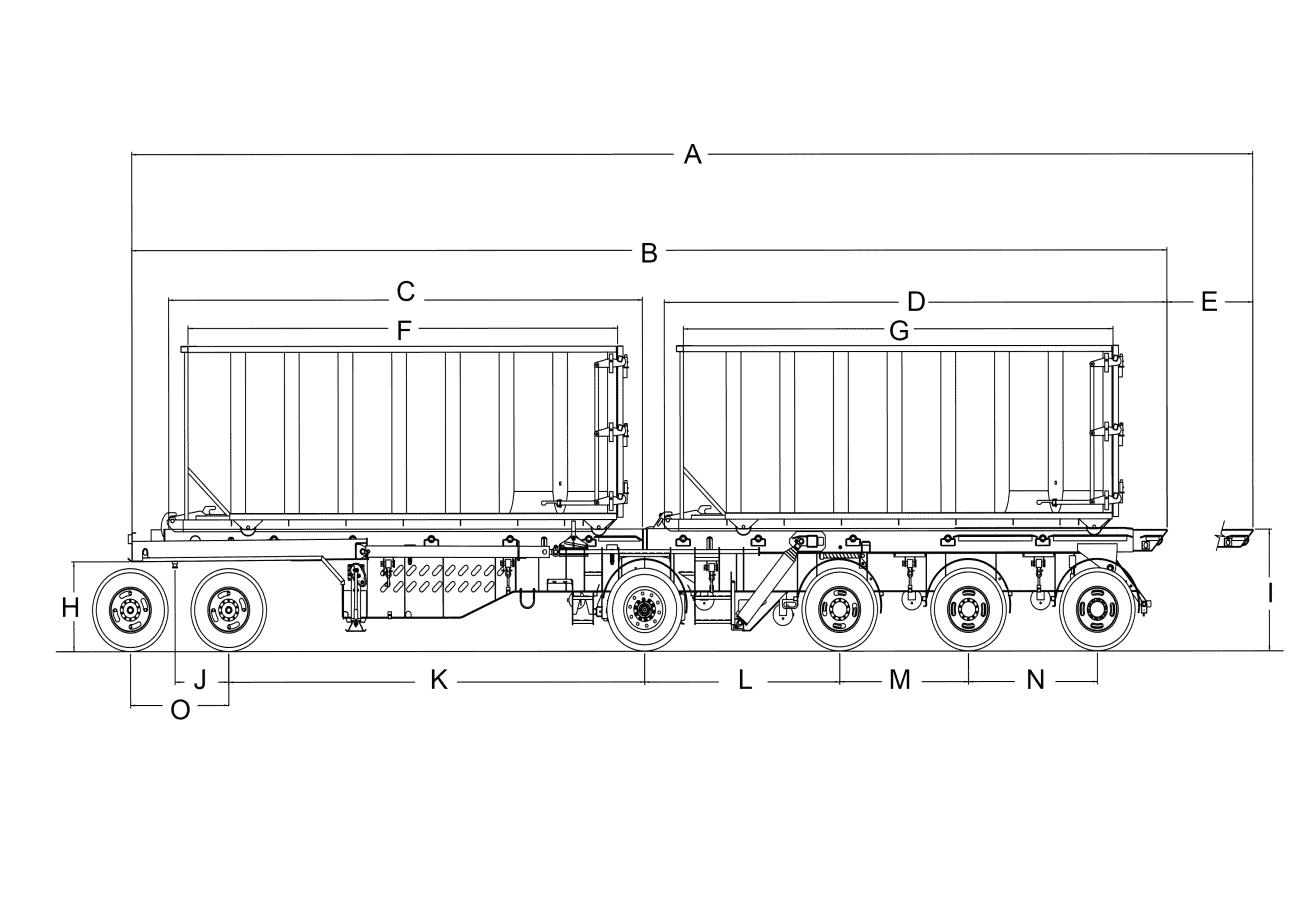

* The parameters and dimensions given above are for guidance only. Actual dimensions may differ.