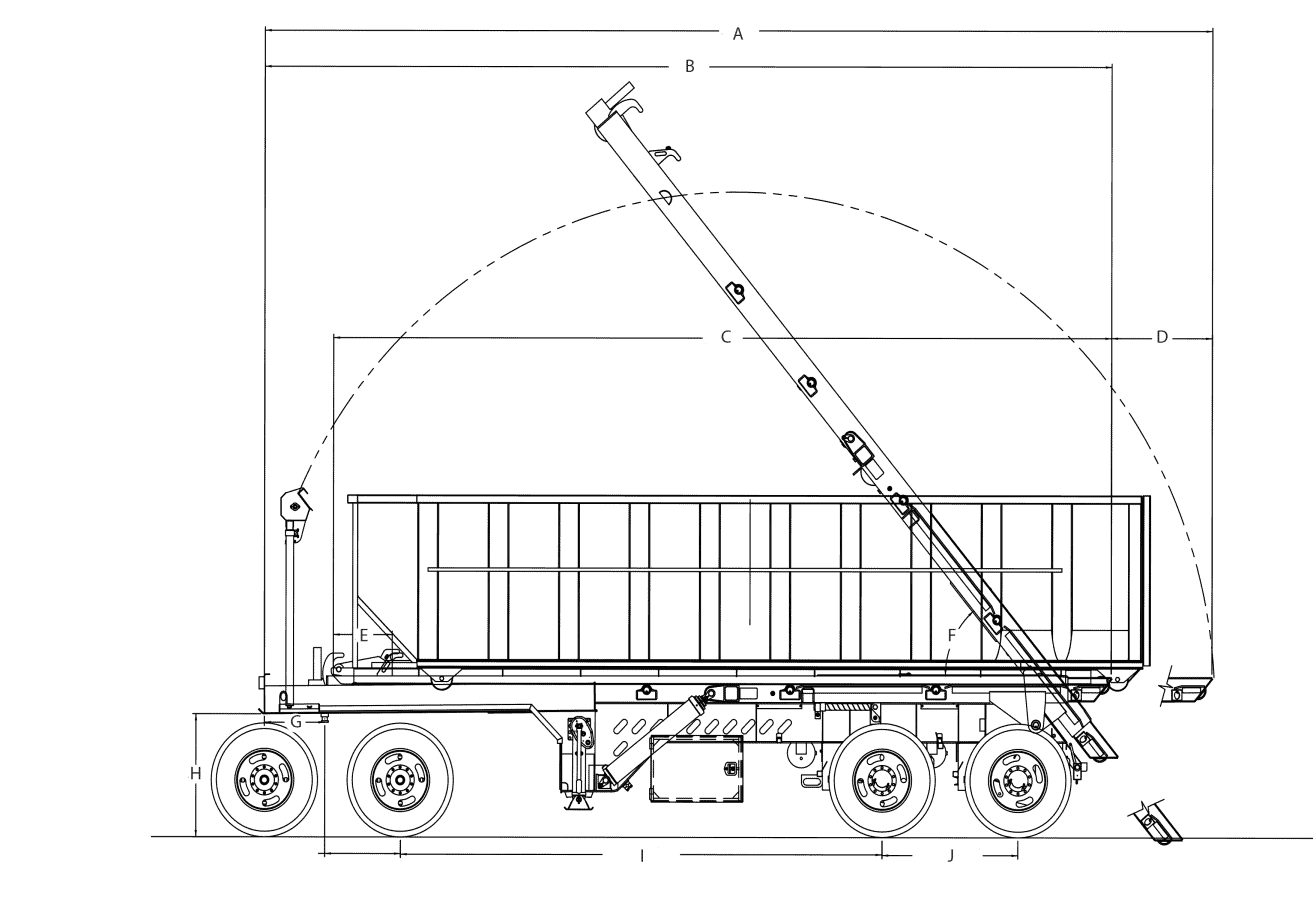

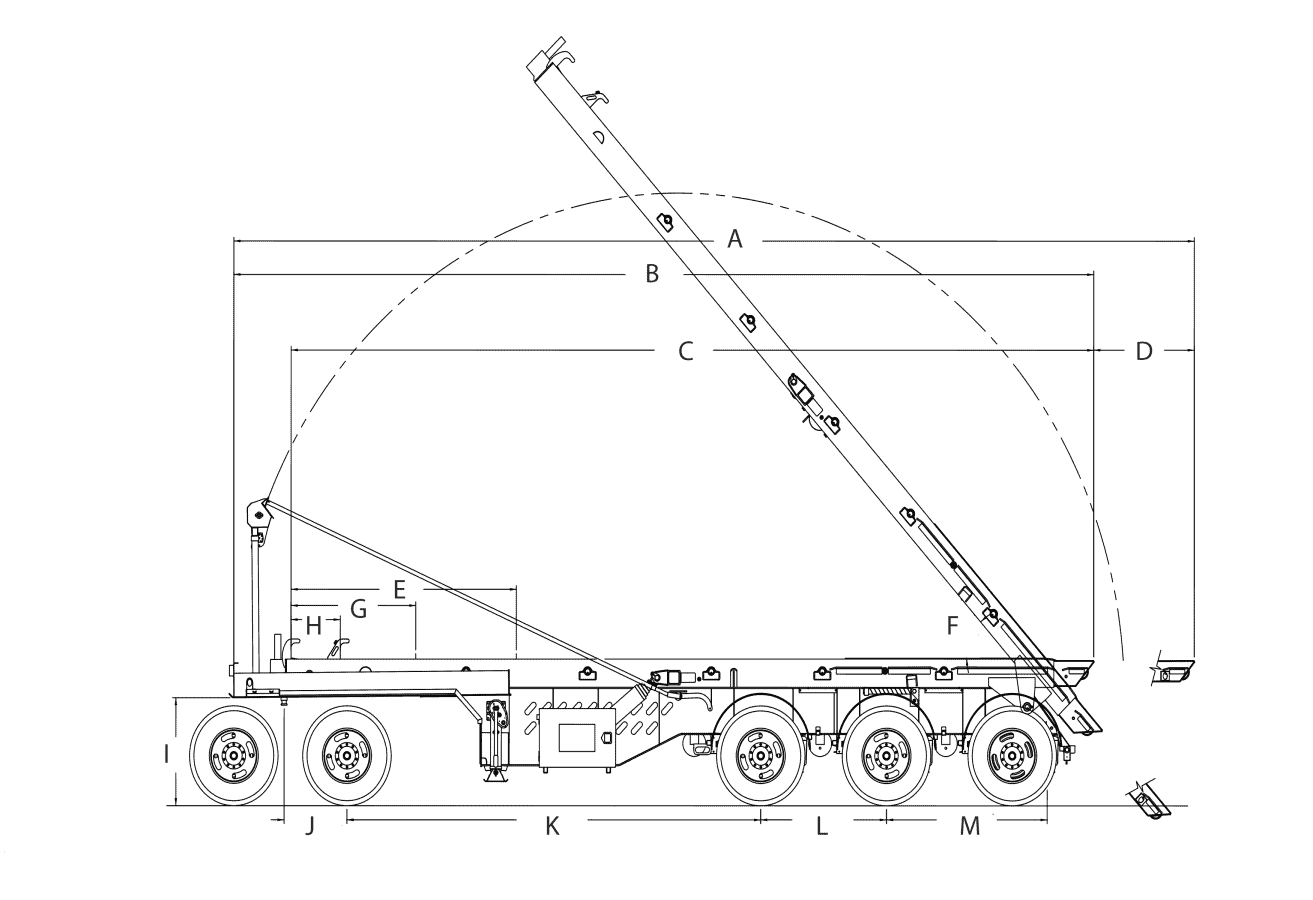

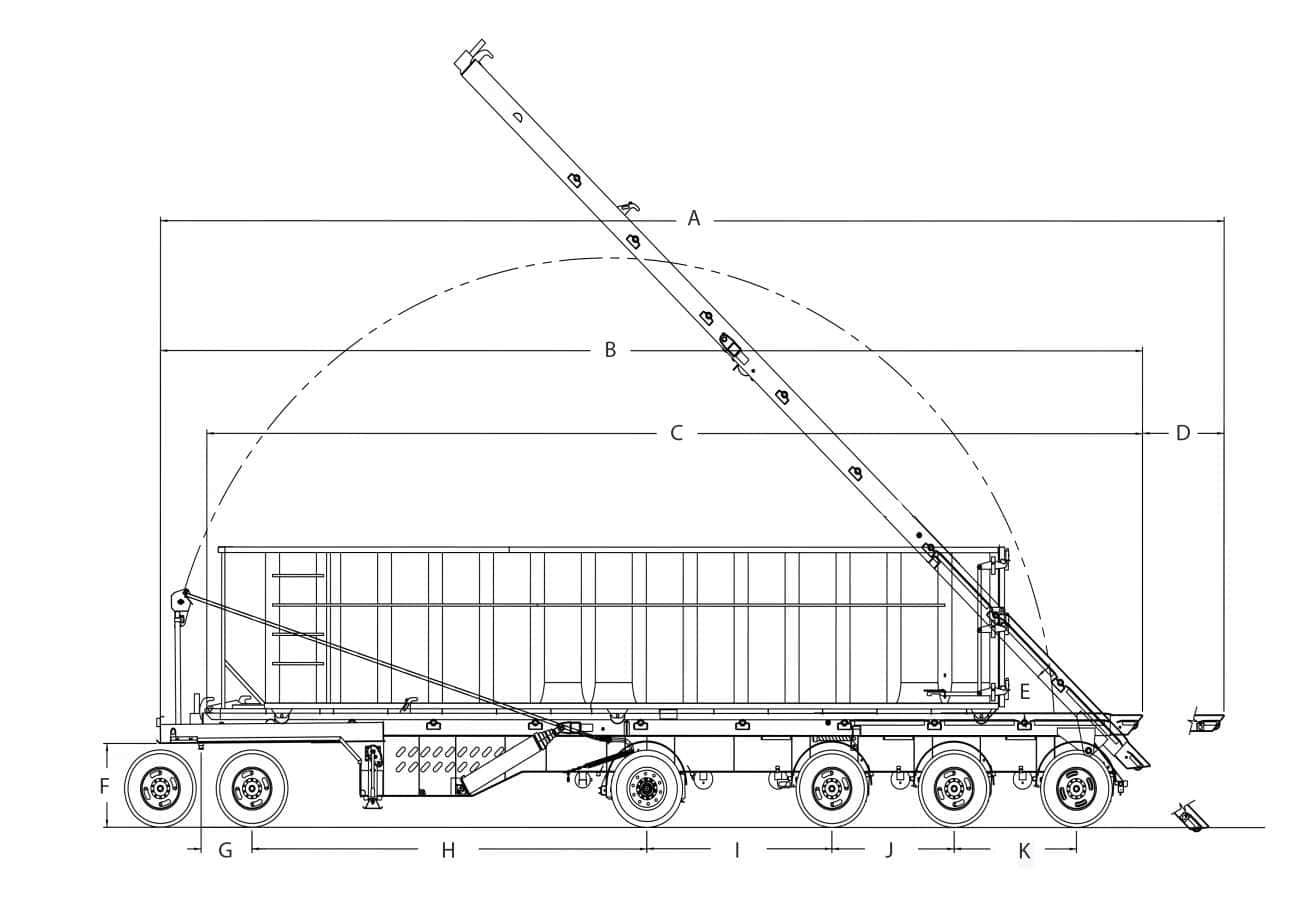

The Straight Deck Roll-Off Trailer, available in 2, 3, or 4 axle configurations, is engineered for optimal container transport. Featuring superior structural strength and constructed with a robust steel frame capable of handling 100,000 lb, this trailer offers a wide wheelbase between lifting cylinders, ensuring a stable and rigid lifting system. It adheres to the ANSI Z-245.60 2008 safety standard, making it a reliable and high-quality choice in the market.

* The parameters and dimensions given above are for guidance only. Actual dimensions may differ.