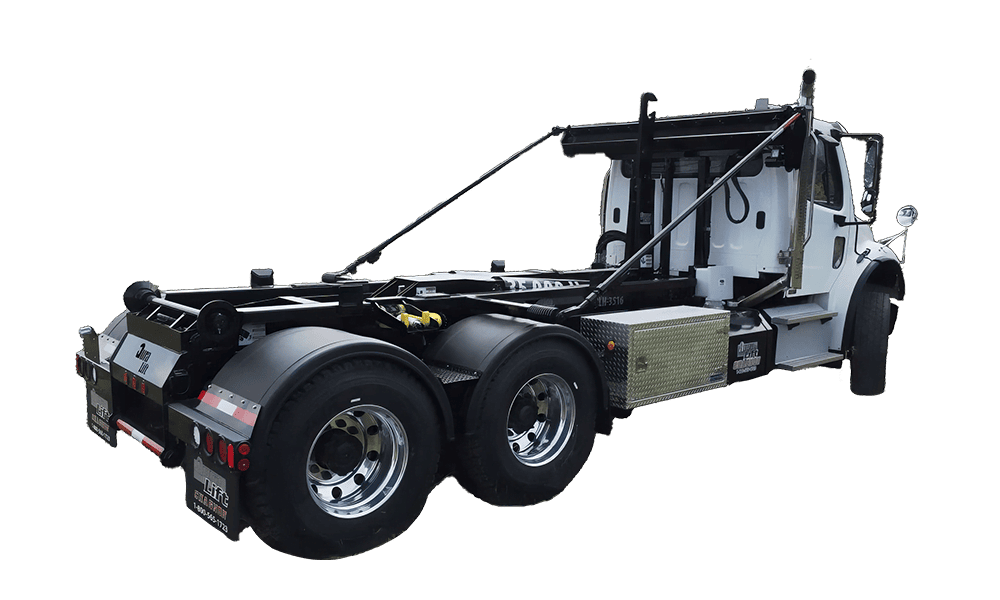

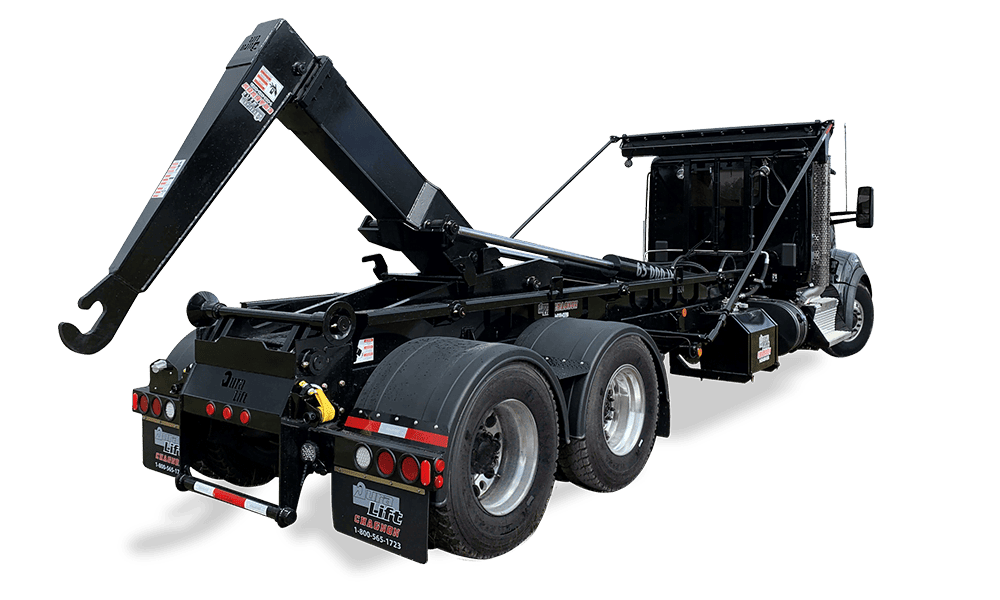

Here is the lifting system with hydraulic winch and roll-off type cable, the most popular roll-off truck in America.

It has been designed to handle and transport all roll-off containers and platforms conforming to ANSI Z245.60 standards.

A set of greasable side rollers reduce friction and allow easier loading and unloading of containers.

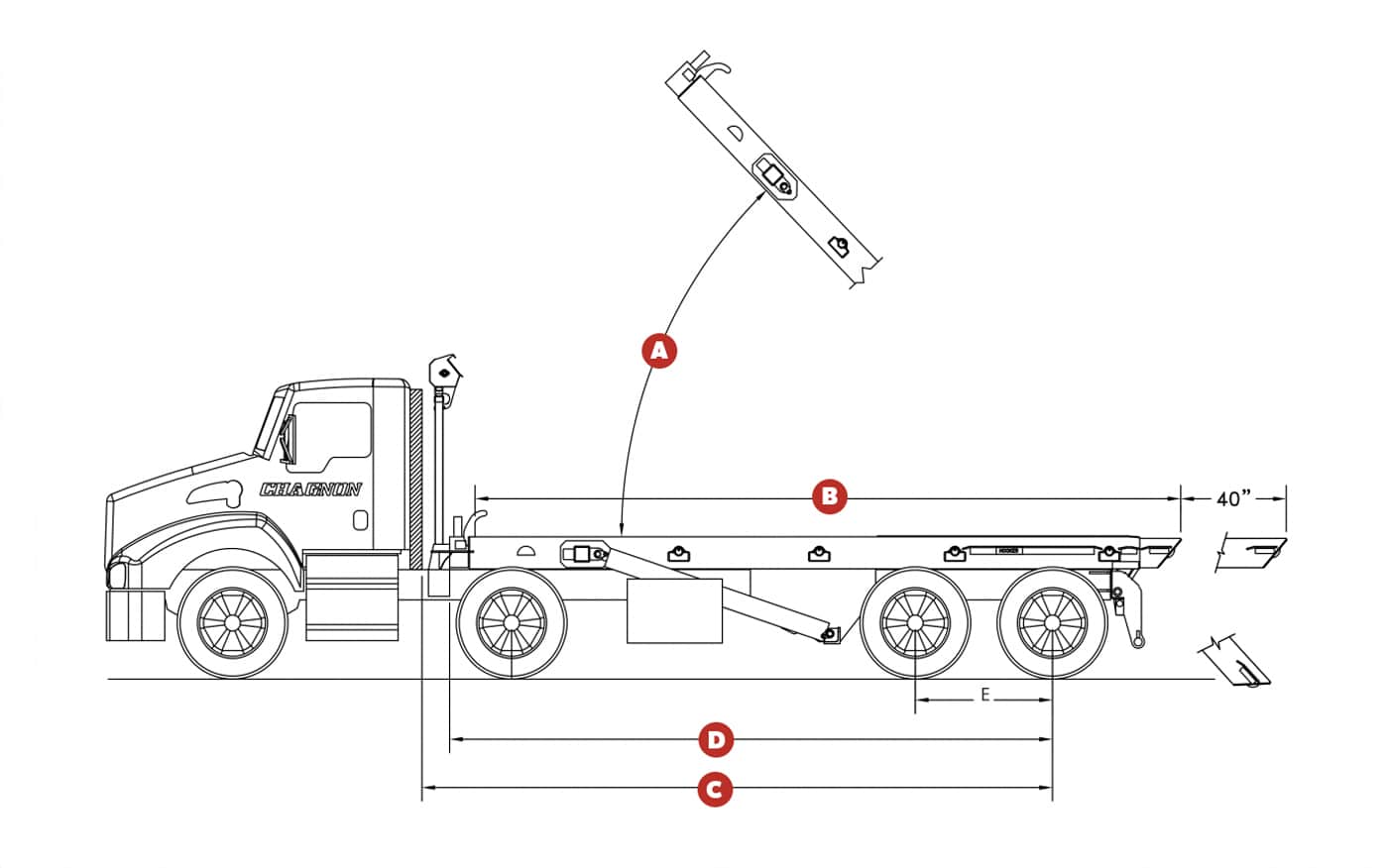

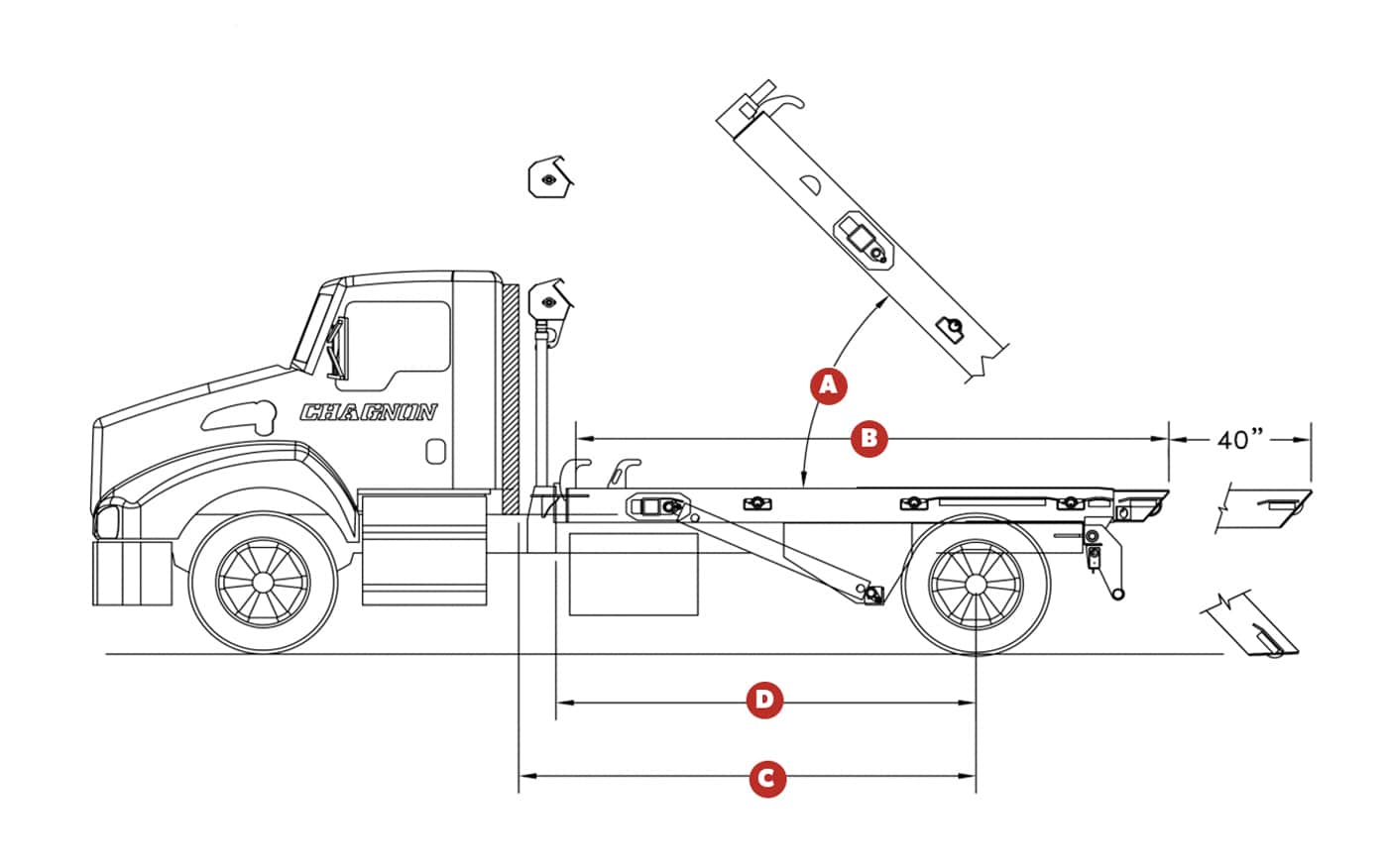

Customize frame based on the chassis, to optimize the space and allow a better load transfer.