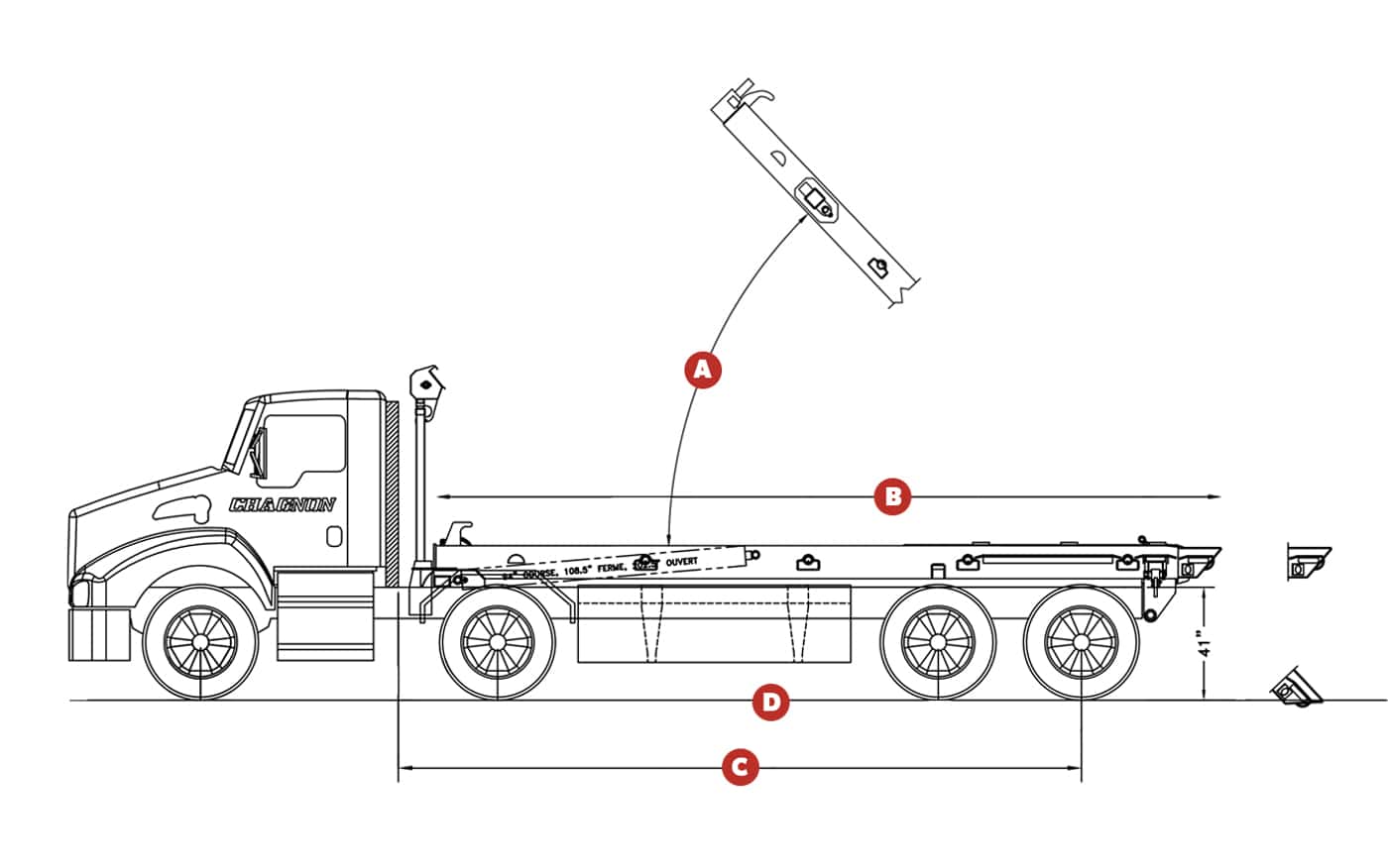

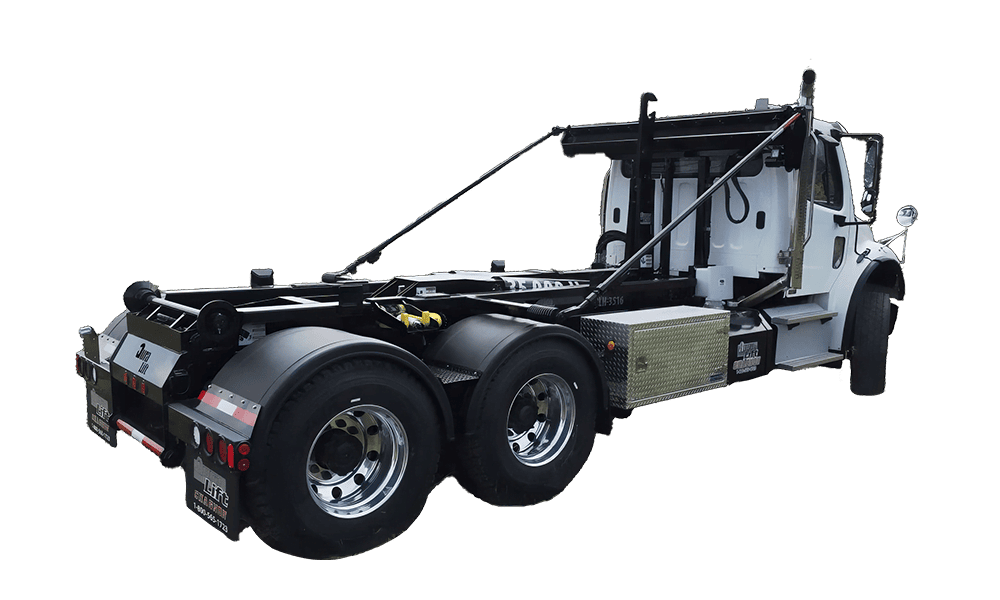

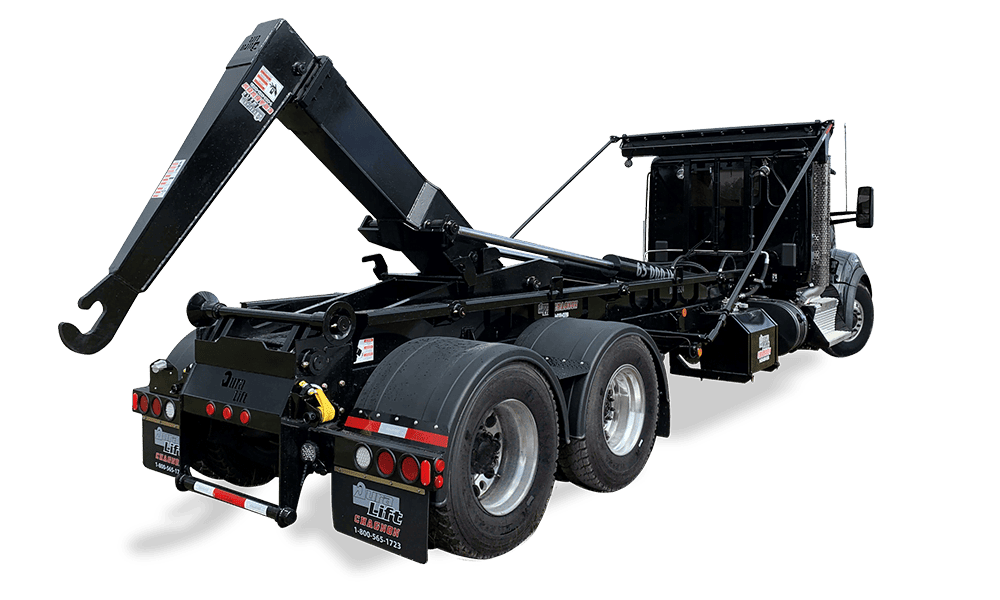

Our DRC-60XX-AF roll-off system is a unique model with hoist lifting cylinders within the lifting hoist frame allowing maximum space for additional options and/or compressed natural gas tanks. With 60 000 lb or 75 000 lb of total capacity and a 7/8″ hoist cable (6X36 – 79,500 lb), it is designed for sturdiness and superior quality. Available in 23′ and 25′ length, it is easy to operate and maintain and its assembly quality exceeds all industry standards (ANSI Z245.1, CSA W47.1, FMVSS/CMVSS, WASTEC, ect.).

* The parameters and dimensions given above are for guidance only. Actual dimensions may differ.